Potassium Sulphate Equipment with Mannheim Furnace 40 TONS/DAY

Potassium Sulphate Equipment with Mannheim Furnace 40 TONS/DAY

Potassium Sulfate SOP is a kind of chlorine-free, high quality and efficient potassium fertilizer. Especially in the cultivation of chlorine-sensitive crops such as tobacco, grapes, beets, tee trees, potatoes.

The potassium sulfate fertilizer K2SO4 is produced from Potassium Chloride KCl/MOP and 98% Sulfuric acid by Mannheim Furnace based on German Mannheim Furnace, by working over its principle and construction, we improve the construction and material of furnace to achieve even heating, complete reaction and low energy consumption. New material and technology is applied to the part of hydrochloric acid absorption, thus absorption efficiency is enhanced and environmental issue is also well resolved.

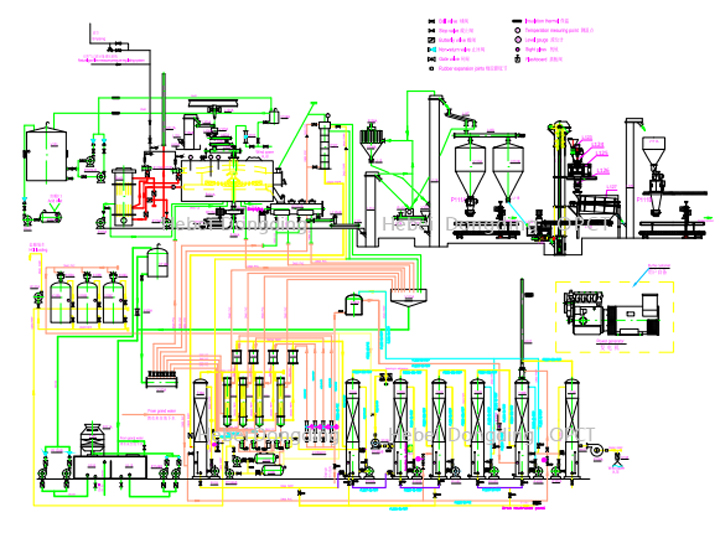

Equipment Description of SOP plant

The potassium sulfate fertilizer produced by the Mannheim furnace designed by our company has high purity, high conversion, simple operation and strong production capacity. Mannheim furnace is mainly composed of combustion chamber (upper part), reaction chamber (middle part), flue chamber (lower part), and is equipped with feeding and mechanical stirring devices. In addition to the Mannheim furnace, the entire potassium sulfate production line also includes feeding system, hydrochloric acid absorption environmental protection system, finished product system, cooling water system, combustion system, storage system, control system, and laboratory equipment.

Production Process of potassium sulfate fertilizer line

A fixed bed (acid liquid salt solid) metathesis reaction method is adopted. Solid potassium chloride and 98% sulfuric acid are continuously added to the reaction chamber in a certain proportion, and the reaction is carried out under the conditions of high temperature higher than 500°C (generally controlled at 540-560°C) pushing the rake teeth to push the material (stirring and mixing). Under the condition of maintaining the normal bed surface, the raw material is continuously input, and the finished product potassium sulfate is continuously discharged from the outlet of the reaction chamber (two symmetrical places) into the finished product pusher, and enters the belt conveyor through the air-sealed conveyor under the conditions of cooling and stirring and crushing., And then crushed into the finished product bunker through a sieve crusher. The hydrogen chloride gas produced in the reaction is absorbed by water to prepare hydrochloric acid and put it into HCl storage tank. It is expected to be discharged into the atmosphere on the premise of meeting the national exhaust gas emission standards.

As we all know, there are two popular methods for the production of potassium sulfate products, one is the metathesis method, the reaction is not good, and the product quality needs to be improved. Another method is the Mannheim furnace method, which is widely used but presents some difficulties in the production process. We have made necessary and important improvements and improvements to the production equipment and production process of its Mannheim furnace, formed a unique and perfect potassium sulfate production process, improved the structure and materials of the furnace, and achieved uniform heating and complete reaction. Low energy consumption.

The core is a new type of reactor updated on the basis of the dry burning method to produce potassium sulfate. With the support of special equipment, the process problems of wear, corrosion and continuous output under high temperature and strong acid conditions are solved. Compared with other similar equipment, it has the outstanding characteristics of less investment, short construction period (4-6 months), high atomization degree, reliable quality, high heating efficiency, high output and environmental protection.

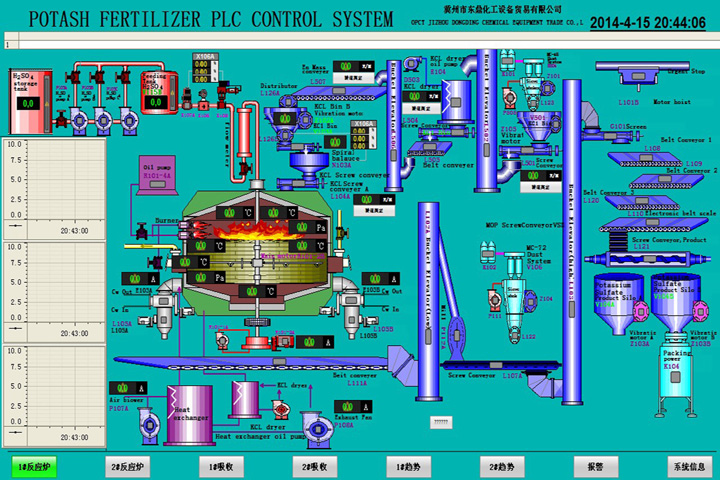

Control System of Mannheim Furnace

Application