Molded FRP Grating & Fiberglass grating

Molded FRP Grating & Fiberglass grating

Hebei Dongding OPCT company produce and sales all kinds of grating based on different resin and yarn according to customers’ requirement. If you need further fiberglass floor grating information or would like to submit a request for quote, (RFQ), please contact with us.

Molded FRP Resin System Option

● Phenolic (Type P): The best choice for applications requiring maximum fire resistance and low smoke emissions such as oil refineries, ships and train decks.

● Vinyl Ester (Type V): Developed to withstand the harsh chemical environments found in chemical, waste treatment and metal plating plants.

● Isophthalic Polyester (Type I): A good choice for environments where chemical splashes and spills are a common occurrence.

● Food Grade Isophthalic Polyester (Type F): Ideally suited for food and beverage industry environments that are exposed to harsh cleaning chemicals.

● General Purpose Ortho Polyester (Type O): Cost-effective alternative to vinyl ester and isophthalic polyester products.

Molded Fiberglass Grating Characteristics

● Strength: Interwoven square mesh construction offers bi-directional strength. This construction allows for increased loading versatility when compared to rectangular mesh. The uniform placement of the continuous glass strands during construction provides superior strength.

● Corrosion resistance: Molded grating should be the product of choice for severe corrosive environments. The one-piece fabrication and complete resin coverage adds to the natural chemical resistance of the materials used in our molded fiberglass grating. You also get excellent resistance to moisture, humidity and bacterial growth for food and medical-related facilities.

● Fabrication features: In areas that require circular cuts or areas to be field cut and fabricated, molded square mesh offers great versatility and will often eliminate the need for additional support for cut edges. Another feature is its easy adaptability to evaluated floor systems through use of special leg pedestals. The pedestal flooring system helps compensate for an uneven sub-floor or slope.

● Cost-Effective: When weighing options for grating materials, molded FRP is a great choice in the long run. There is less waste when installing due to its interwoven square mesh construction. It is also long-lasting and is low maintenance.

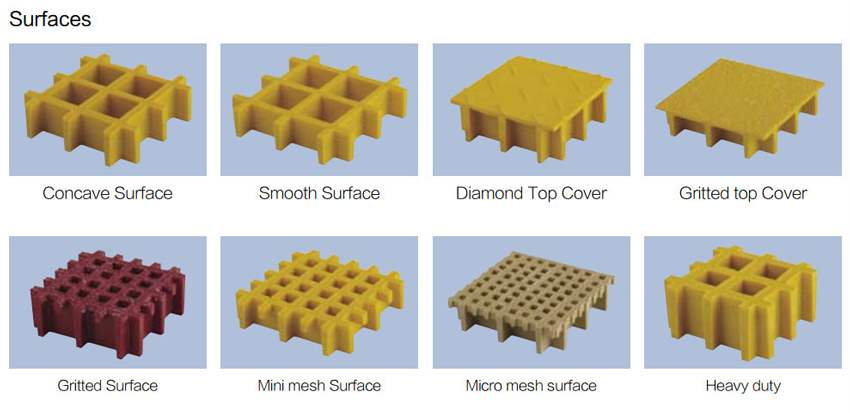

● Safety surface: Molded Grating offers an outstanding skid resistant concave surface as an option. A molded-in grit surface is also available to provide sure footing for worker safety, yet its non-porous qualities help eliminate bacterial breeding areas in food applications.

Molded GRP Grating Type

Molded Fiberglass Resin Grating Size

Thickness (mm) | Mesh (mm) | Weight (kg/m2) | Mold size (m) |

25 | 40*40 | 11.5 | 1*4 |

1.22*3.66 | |||

38*38 | 12 | 1*4 | |

1.22*3.66 | |||

30 | 40*40 | 14 | 1*4 |

38*38 | 16 | 1.22*3.66 | |

38 | 40*40 | 18.5 | 1.22*3.66 |

38*38 | 20 | 1.22*2.44 | |

1.22*3.66 | |||

1*4 | |||

50 | 50*50 | 21.6 | 1.22*3.66 |

1*4 | |||

38*38 | 27 | 1*4 | |

65 | 50*50 | 29 | 1.22*3.66 |

38*38 | 36 | 1*4 | |

1.22*3.66 | |||

38 cross mesh | 38*(19*19) | 23 | 1.22*3.66 |

30 cross mesh | 50*50*(25*25) | 14.5 | 1.22*4.025 |

38*(19*19) | 18 | 1*4 | |

25 cross mesh | 50*50 | 12 | 1.22*3.66 |

1*4 | |||

38*(19*19) | 16 | 1*4 | |

40 mini mesh | 38*(13*13*13) | 1.22*3.66 |

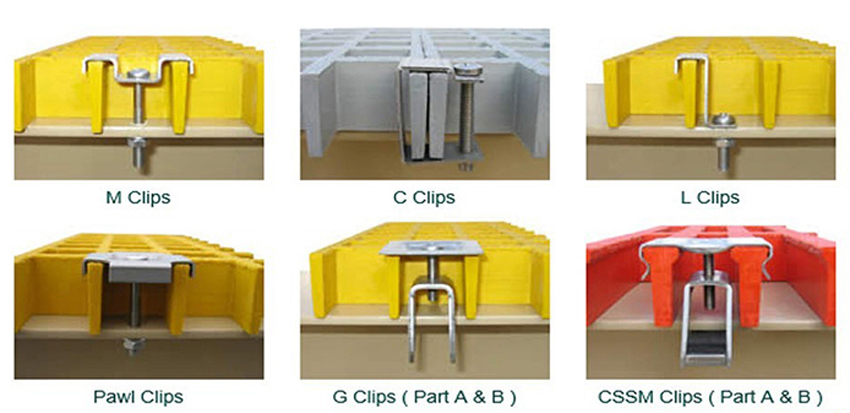

Molded Fiberglass Grating Fasteners and Accessories

● Industrial areas: such as chemical plants / plating plant operating platform, maintenance platform,photovoltaic power generation platform walkway

● Sewage treatment areas: sewage treatment plant aisle and sealing cover

● Municipal Engineering areas: Pedestrian Walkway, Trench / Cable Trench Cover, Tree Grating

● Marine applications area: Boat decks or bridge materials, Offshore oil platform

● Other civilian areas: such as car washing, cattle and sheep farms and so on

● Fiberglass grate floorings are non-corrosive, readily available, and inexpensive, thus increasing their use in industrial settings.