Mannheim's New Technology to Improve Potassium Sulfate Production

I. Process technology

Mannheim method of potassium sulfate is named after the production of potassium sulfate using a mechanical sulfate furnace developed by German expert Mannheim. It is also an old traditional process. The thermal decomposition reaction between sulfuric acid and potassium chloride produces potassium sulfate and hydrochloric acid by-product. After 26 years of further optimization since the process was introduced to the mainland from Taiwan in 1997, it has developed into one of the most advanced and mature potassium sulfate production processes in the world and has been occupying half of the potassium sulfate production in China.

II. Process improvement

1. Improvement of production equipment

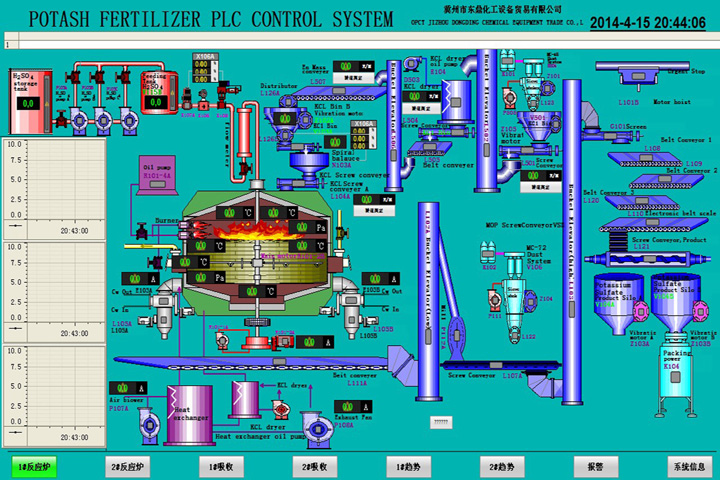

The reaction of the Mannheim process for the production of potassium sulfate by thermal decomposition takes place in the Mannheim furnace, with a reaction temperature of 520-540°C. Therefore, the reaction furnace is the key to this process. Therefore, the reaction furnace is the key equipment of this process, and its performance directly affects the production cost of this process.

In view of the defects of the traditional Mannheim process, the new process is improved mainly in the following points.

(1) Improvement of the reactor structure and materials, so that the problems of corrosion and high temperature resistance of the furnace internals can be successfully solved.

(2) New materials and processes are adopted in the absorption part of hydrogen chloride to improve the absorption rate, so that the material is evenly heated, the reaction is complete and the three wastes are discharged to the standard.

(3) Automatic acid measurement of hydrochloric acid.

(4) The safety performance of the automatic valve of the reactor has been improved to ensure safe production.

The new process has greatly exceeded the German standard and is at the world leading level. At present, it has been applied in more than 20 countries such as Philippines, Indonesia, Egypt, India, Jordan and Iran.

2. Economic efficiency improvement

(1) 60% reduction of equipment maintenance cost.

(2) Energy consumption is reduced by 20%.

(3) About 20% increase in unit yield.

(4) Management costs are reduced.

III. Cost estimation

Take the annual output of 40,000 tons of potassium sulfate as an example.

Potassium sulfate product 40,000 tons/year, product quality in line with GB 20406-2017 first class standard, of which, K2O ≥ 50.0%, Cl- ≤ 2.0%.

Total hydrochloric acid by-product (A acid + B acid): 47,520 tons.

The production ratio of A acid to B acid is not less than 9:1;

The quality of A acid product meets the requirements of GB320-1993 standard qualified product, i.e. HCl≥ 31.0%

B acid contains 1~5% sulfate and a small amount of metal ions.

(1) raw material specifications and consumption

Potassium chloride: K2O ≥ 62.0% (imported), 33,200 tons/year

Sulfuric acid: 22,800 tons/year, 98% industrial sulfuric acid standard first grade (GB/T532-2002).

Calcium carbonate: 1600 tons/year, particle size of 60-100 mesh.

(2) Power consumption

Natural gas: ≥ 303 m 3 / h.

Electricity consumption: 2.4 million kWh/year (303 kWh/h)

H2O: 6.1m3/hour.

Circulating water: 10.1m3/hour