FRP GRP Electrolytic Cell Introduce

Typical Cell Construction Features

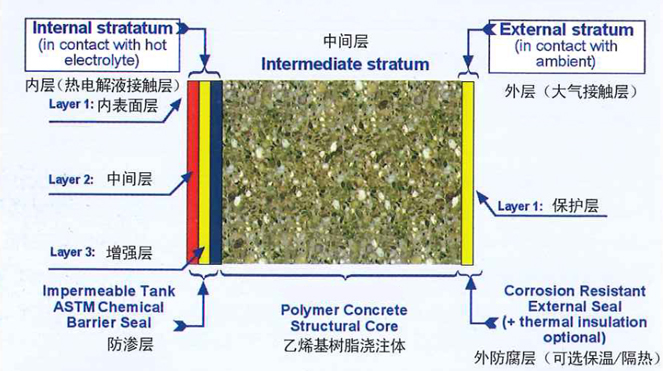

Fiberglass reinforced electrolytic cells are manufacture with proprietary ”tri-stratum polymer composite material”. This material consists of three monolithically bound layers.

1. An electrolyte FRP seal or chemical barrier

2. A structure core made with polymer concrete (aggregate reinforcement grading according to US Pat #6143219) and

3. An external FRP seal

The polymer concrete structural core and both FRP seals are manufactured to ensure a high quality chemical bond between the three strata, forming a cohesive, monolithic composite material with very high chemical and mechanical strength. The formulation and properties of this composite material have been tailored for best performance electrolytic cells.

The electrolyte seal complies with sections of norms DIN18.820-3 and ASTM C582 regarding chemical barriers for FRP tanks. These forms have been validated by more than 40 years of successful industrial experience. This seal typically consists of three layers of fiberglass impregnated with vinyl ester resin (see diagram above).

The external seal is manufactured with same care and quality as the electrolyte seal. Although with only one FRP layer it done not comply with the above standards.

Both seals can be inspected according to norm ASTM D4097 Class IV. As an option the seals may be pigmented white, gray or other color favorable to refinery operation or purchase preference.

Electrolytic Cell Benefits

Guaranteed Long-Term Impermeability, Free of Corrosion---Designed with a monolithic impermeable internal tank manufactured with multiple layers of fiber-reinforced premium vinyl-ester resin.

Minimum Cleaning Time and Water Consumption---The rounded internal shape, optional sloped cell floors, and smooth, flat finish of the internal tank, facilitate water sweeping and drainage of heavy sludge, with reduced water usage and accelerating return to service after each cleaning.

Minimum Maintenance Cost---The robust, virtually impervious internal tank that is chemically bound to the polymer concrete structural core during molding is tolerant to operating abuse. It is smooth, non-stick surfaces minimize adhesion of contaminants.

Maximum Operational Safety---The structural core of electrolytic cells is bolstered with sturdy external seismic reinforcement blocks confining its floor supports, and includes a robust, internal bidirectional , pultruded FRP bar mesh reinforcement which positively maintains integrity should the cell fail due to catastrophic events. The electrolytic cell installation protocols call for lateral wall collaboration between cells , thus reducing stress levels of cell around 40% under normal operating conditions.

Key Accessories Integrated with Electrolytic Cell Engineering--- When Hebei Dongding (OPCT) designs and manufactures cell thermal insulation, capping board and electrolyte agitation systems that can be incorporated in the cells, enhancing overall safety, cathode quality and tank house productivity.